Powering Smarter Manufacturing with Unified Business Software

Kerridge Commercial Systems brings together the best of Omni Accounts, Palladium Business Solutions, and IQ Retail to deliver a future rich ERP software for the manufacturing industry. Our software is trusted by thousands of businesses.

Optimized Production Planning

Integrated Accounting & Financial Control

Inventory & Supply Chain Visibility

Smart Integrations for ease of use

Modular & Scalable for Growth

Real-Time Data & Reporting

Built on Proven Solutions. Unified for Your Success

KCS Manufacturing Software harnesses the power of industry-leading innovations from Omni, Palladium, and IQ Retail. Now unified, we deliver a comprehensive, flexible platform tailored for the manufacturing industry.

- Streamline production processes with real-time data insights, enabling proactive decision-making and reducing downtime.

- Enhance operational efficiency through seamless integration with existing systems, ensuring a unified approach to manufacturing management.

Let’s Talk Manufacturing Software

Get a personalized walkthrough of how Kerridge Commercial Systems (KCS) manufacturing software can streamline your production, improve efficiency, and grow your business.

Book your demo now and discover how we can help you source effectively, stock efficiently, sell profitably & service competitively.

Omni Accounts, Palladium Business Solutions, and IQ Retail are subsidiaries of Kerridge Commercial Systems, consistently providing value while enhancing customer offerings.

Transform your business with our manufacturing software

We offer businesses a comprehensive end-to-end business solution catering from all aspects of the business from Accounting, Manufacturing, Point-of-Sale and Distribution, right through to RPA (Automations and Notifications), eCommerce Integrations, Mobile Warehousing, Mobile Salesforce and Deliveries, as well as a complete Payroll offering. Our software features are also developed on 3 core business success values of Increasing Turnover, Optimising Margins and Improving Operational Efficiency.

Change to KCS Manufacturing and let us take your business “Beyond Accounting”

Key manufacturing industries:

Paint manufacturing

Chemical manufacturing

Automotive parts & coach software

Food & beverage manufacturing

Electronics manufacturing

Furniture & home stores manufacturing

Fashion & textile manufacturing

Packaging & printing manufacturing

Personal protective equipment (PPE) products manufacturing

Agriculture & farming manufacturing

Metal & machinery manufacturing

Building material & construction manufacturing

Health & beauty manufacturing

Electrical manufacturing

"Changing to Omni was the best decision we made, it is extremely user friendly and the support line is very efficient with any queries which may arise."

Software for the Manufacturing Industry

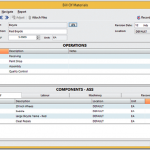

Assembly on the Fly (Kitting)

Kerridge Commercial Systems (KCS) Manufacturing offers flexible solutions for manufacturing needs. Open a job to produce multiple items and by-products, adding costs as needed. Manufacture on the fly with components drawn at invoicing. Utilize the Un-Manufacture Facility for reverse processes, like breaking down a carcass or decanting liquids. Set a Standard Bill of Material for predefined quantities, such as 1000L of paint, simplifying the process. The Kit-On-The-Fly feature lets you price and invoice set quantities, efficiently managing inventory.

Assemble & Disassemble

Create assembly or disassembly processes to manufacture one or more items at a time. Disassembly, strips inventory items into component parts, this creates a simple disassembly transaction and is ideal for manufacturers needing a simple method to take apart an item and get the components back into inventory.

Process Manufacturing & WIP

Optimize your manufacturing process with KCS Manufacturing. Utilize work centres and manage inventory issues for comprehensive Work-in-Progress (WIP) and process manufacturing, incorporating both fixed and variable overhead rates for labor and machinery. This feature operates independently from the Assembly Function, enabling you to create jobs, set up work centres, and post WIP costs, including inventory, service, labor, machinery, and overheads. Upon job completion, costs are transferred from WIP to finished goods. The Bill of Materials screen allows you to assign or issue inventory, labor, machine, and overhead costs per work centre, ensuring precise cost analysis and variance control.

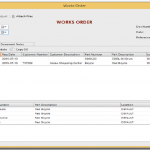

Works Order

A new works order function allows you to create a Works Order from a Production Schedule, added Manually or Copied from a Sales Order. Copying from a Sales Order allows you to track the Customer Details throughout the manufacturing process. The purpose of the Works Order function is to allow you to print a bulk, or Combined Materials Issue for the store. If you refer to the screen you will see that when we select the Item to Manufacture on top, that the components are listed on the screen below for greater detail.

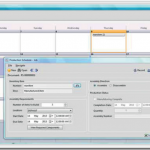

Schedule Calendar

You can now add planned jobs to a Graphical Work Schedule in Calendar Format that allows the production manager to view jobs scheduled for a specific period such as day or month.

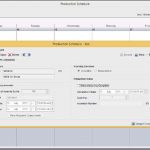

Manufacturing Production Schedule

Here you can create a planned production schedule with expected production dates to better manage your production in a Calendar View. Items entered will create demand for the various raw material components ensuring timely procurement and ordering.

Contact us now to discover how we can enhance your accounting and manufacturing operations

Save time with fast and transparent batch tracking

Our manufacturing software features batch and serial number tracking for companies dealing with high-value or regulated goods. Such tools feature full traceability throughout the supply chain, helping you manage warranty claims, product returns, and recalls. Also, you can quickly trace any product from its origin to its final destination, ensuring compliance with industry regulations and customer peace of mind.

- Track individual lot and serial numbers for those products considered high-value and(or) regulated.

- Ensure fast and clear traceability for managing recalls, warranty claims, and returns.

Enhance your quality control processing

Our manufacturing software empowers businesses to maintain the highest standards of quality by providing customisable tools for implementing and managing quality control (QC) processes. This means you can tailor QC protocols to fit the unique requirements of each product you manufacture. Whether dealing with different materials, processes, or customer specifications, you can design specific quality checks to monitor every production stage.

- Design QC protocols that fit the needs of specific products or production lines.

- Identify defects early in production to reduce waste and minimise rework.

Get the edge with improved maintenance and asset management

Our system uses Preventive Maintenance Scheduling to track equipment usage across your region. Moreover, it automatically schedules preventive maintenance based on predefined intervals or user-initiated requests. Therefore, you can rest assured that your machines have been optimised for performance, helping reduce downtime and extend equipment life.

- Removed guesswork and speed up decisions with scheduled preventive maintenance based on real-time data.

- Minimise costly and unexpected breakdowns while maximising the lifespan of your machines.

Gain full control of your finance

See the difference costing and financial tracking can make as you calculate production costs and compare them against previous budgets. With our manufacturing software, you can use budget and forecasting features to plan better for the future, tracking key financial metrics such as profit margins and cash flow. The software also simplifies accounts payable and accounts receivable, ensuring that financial transactions are aligned with production and order fulfilment processes.

- Stay on top of your budgets by tracking costs effectively throughout all areas of your business.

- Manage all your invoices, payments, and collections with from one central location.

Regulatory compliance and traceability

Ensure compliance with industry regulations through comprehensive traceability features. We equip your business with the power to fully trace everything from raw materials used right through to batch delivery, allowing manufacturers to quickly identify the origin of any issues. This feature supports product recalls, warranty claims, and safety standard compliance, keeping your business, products, and reputation safe at all times.

- Track products from raw materials to delivery for full and fast, hassle-free compliance.

- Need to recall a product? Our manufacturing software enables easy management of product recalls and warranty claims.

.jpg?width=700&height=700&name=Manufacturing%20page-business%20intelligence%20(BI).jpg)

Powerful data analytics and business intelligence (BI)

Get valuable insights with our software's advanced data analytics and business intelligence tools. Instead of waiting days, you can now create in-depth production and performance reports at the touch of a button to analyse efficiency, pinpoint bottlenecks, and streamline processes. Real-time dashboards provide live updates on production status, machine uptime, and quality control metrics, empowering data-driven decision-making and continuous improvement.

- Gain access to fully customisable real-time dashboards for immediate insights.

- Enhance your production processes with in-depth performance reports.

Expand effortlessly with smart integrations and the power of scale

Our manufacturing software is a fully integrated ERP solution that delivers seamless visibility across production, supply chain, financial, and workforce management. With the flexibility of cloud and mobile access, you can effortlessly expand your operations and oversee your business from any location, ensuring uninterrupted workflow across multiple sites. This dynamic and adaptable solution empowers manufacturers to streamline operations, minimise waste, enhance quality, and uphold regulatory compliance, all while gaining a competitive edge in the market.

- Scale your operations easily and at reduced cost with our cloud-based solutions.

- Access real-time data and manage remotely from any location with an internet connection.

Recommended manufacturing software

Engineered to optimise operations, strengthen financial oversight, and deliver real-time insights, Palladium is your all-in-one business partner with the full suite of digital tools to help your organisation excel.

Key features:

- Streamline processes with integrated accounting

- Gain comprehensive control of your stock

- Drive efficiencies in manufacturing

- Manage projects with integrated budgets

Our configurable software solution empowers small to medium enterprises to manage all aspects of their business efficiently. With short implementation timescales, you see a rapid return on your investment.

Key features:

- Intuitive, rapid to implement and easy to use

- Multi-company and multi-branch operations

- Fully integrated suite of financial ledgers

- Strong inventory and production control

- Powerful reporting & analytics to drive profitability

Our cloud-based ERP solution empowers small to medium enterprises across South Africa to manage all aspects of their business efficiently. And it's quick to learn for a fast return on investment.

Key features:

- Fast & intuitive processing

- Improved sales & purchasing

- Time-saving stock management

- Powerful reporting & analytics